How do your 5-ply and 7-ply boxes compare in terms of strength and durability?

In general, a 7-ply box will be stronger and more durable than a 5-ply box, all other factors being equal. The additional layers in a 7-ply box provide extra reinforcement and resistance to impact, compression, and puncture.

However, the actual strength and durability of a box depend on many factors, such as the type and quality of the materials used, the construction method, and the intended use of the box. For example, a 5-ply box made from high-quality materials may be stronger and more durable than a 7-ply box made from lower quality materials or with poor construction.

When selecting a box, it’s important to consider the specific requirements of your application, such as the weight and fragility of the contents, the mode of transport, and the environmental conditions the box will be exposed to. Consulting with a packaging expert can help you select the most appropriate box for your needs.

What is the maximum weight capacity of your 3-ply boxes?

The maximum weight capacity of a 3-ply box would depend on various factors, such as the size and shape of the box, the type and quality of the materials used, and the construction method.

In general, a 3-ply box may be able to hold up to 40-60 pounds of weight, but the actual weight capacity can vary widely depending on the factors mentioned above. If you have a specific 3-ply box in mind, I recommend checking the manufacturer’s specifications or consulting with a packaging expert to determine its maximum weight capacity.

FAQs on 3 Ply, 5 Ply, and 7 Ply

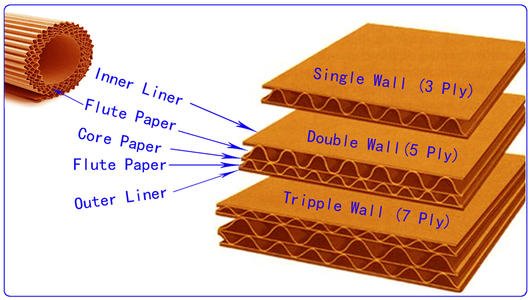

What does the “ply” in 3-ply, 5-ply, and 7-ply refer to?

A: “Ply” refers to the number of layers or sheets of material used to construct a box. For example, a 3-ply box has three layers of material, a 5-ply box has five layers, and a 7-ply box has seven layers.

How do 3-ply, 5-ply, and 7-ply boxes differ in terms of strength and durability?

A: Generally, a higher ply count means a stronger and more durable box. This is because additional layers of material provide extra reinforcement and resistance to impact, compression, and puncture. However, the actual strength and durability of a box depend on many factors, such as the type and quality of the materials used, the construction method, and the intended use of the box.

What materials are typically used to make 3-ply, 5-ply, and 7-ply boxes?

A: Boxes can be made from a variety of materials, including corrugated fiberboard, cardboard, paperboard, plastic, and metal. However, most commonly, ply boxes are made of corrugated fiberboard, which consists of a fluted sheet sandwiched between two flat sheets of paperboard.

What are the most common uses for 3-ply, 5-ply, and 7-ply boxes?

A: These boxes can be used for a wide range of applications, including shipping, storage, and packaging of various products such as electronics, food, beverages, and household items. However, the specific use of a box will depend on its strength, size, and other features.

Can the ply count be customized for a specific box?

A: Yes, the ply count can be customized for a specific box based on the requirements of the application. However, a higher ply count may increase the cost of the box. It’s important to consult with a packaging expert to determine the most appropriate ply count for your needs.

Leave a Comment