How to Calculate Size of Corrugated Box

Calculating the size of a corrugated box involves understanding the dimensions, style, and type of corrugated box required to package a particular product effectively and efficiently. In this comprehensive guide, we will walk through the step-by-step process of determining the size of a corrugated box, taking into account the product’s dimensions, packaging requirements, and shipping considerations. Additionally, we will explore various box styles and types commonly used in the industry.

Understanding Corrugated Boxes

Corrugated boxes are the most widely used packaging solution for shipping and protecting various products. They are made from corrugated cardboard, which consists of three layers: an inner corrugated medium, fluted paper, and two outer flat linerboards. This construction provides strength, cushioning, and durability to the box.

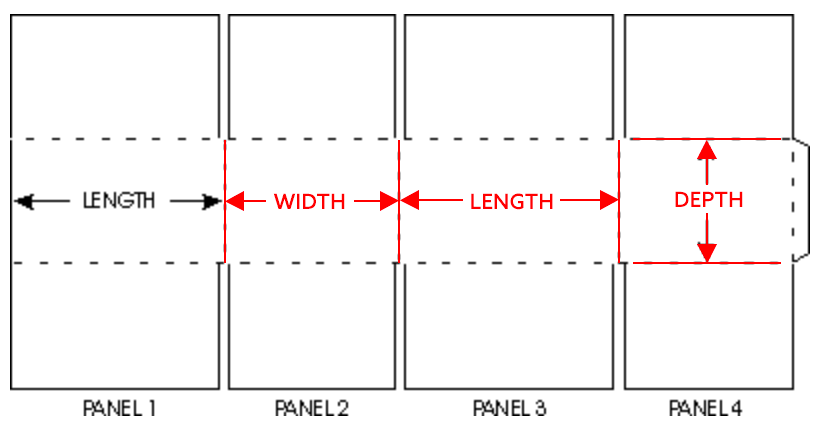

Corrugated boxes come in various sizes, styles, and types to accommodate different products, weight loads, and shipping requirements. The size of a corrugated box is typically expressed in terms of length, width, and height (L x W x H) and is measured in inches or centimeters.

Gathering Product Information

The first step in calculating the size of a corrugated box is to gather all the necessary information about the product that needs to be packaged. This includes the product’s dimensions, weight, fragility, and any special handling requirements. Additionally, consider the quantity of products that will be packed in each box, as this can impact the box size and overall packaging efficiency.

Determining Product Dimensions

Measure the dimensions of the product that needs to be packaged. For regular-shaped items (e.g., rectangular or square), measure the length, width, and height in inches or centimeters using a measuring tape or ruler. For irregular-shaped items, measure the largest dimensions in each direction to ensure that the box can accommodate the product comfortably.

Considering Product Cushioning

Depending on the fragility of the product, you may need to add cushioning materials inside the box to protect it during transit. Common cushioning materials include bubble wrap, foam inserts, packing peanuts, and air pillows. Factor in the thickness and volume of the cushioning material when determining the size of the box.

Calculating Inner Box Dimensions

To calculate the inner dimensions of the corrugated box, add the product’s dimensions to the cushioning thickness on each side. For example, if the product’s dimensions are 10 inches (L) x 8 inches (W) x 6 inches (H), and you use 2 inches of cushioning on each side, the inner box dimensions would be 14 inches (L) x 12 inches (W) x 10 inches (H).

Selecting the Appropriate Box Style

Corrugated boxes come in various styles, each suited to specific packaging needs. The most common box styles include:

- Regular Slotted Container (RSC): This is the most standard box style, with flaps that meet in the center and require tape or adhesive to seal. RSC boxes are versatile and widely used for general packaging purposes.

- Half-Slotted Container (HSC): Similar to RSC, but with only one set of flaps, usually on the top. HSC boxes are often used as lids or covers for larger boxes.

- Full Overlap Container (FOL): This box style has flaps that fully overlap each other, providing extra strength and protection. FOL boxes are commonly used for heavier or fragile items.

- Five Panel Folder (FPF): This style is suitable for long, flat products like mirrors or posters. The box has five panels, with one acting as the lid and another as the bottom.

- Die-Cut Boxes: These boxes are custom-designed and precision-cut to fit the product’s shape perfectly. They are commonly used for electronics, cosmetics, and specialty products.

- Multi-Depth Boxes: These boxes have score lines that allow the height to be adjusted to accommodate different product sizes. They offer flexibility and efficiency in inventory management.

Choose the box style that best fits your product’s dimensions and packaging requirements.

Calculating Outer Box Dimensions

To calculate the outer box dimensions (shipping box), consider the inner box dimensions and add additional space for void fill or packing materials. The additional space allows for proper cushioning and protection during shipping.

Typically, the additional space (fluff space) is around 1-2 inches on all sides. For example, if the inner box dimensions are 14 inches (L) x 12 inches (W) x 10 inches (H), the outer box dimensions would be 16 inches (L) x 14 inches (W) x 12 inches (H) to account for the fluff space.

Determining the Box Strength

The strength of the corrugated box is essential to ensure the safe transportation and protection of the product. Box strength is determined by the type of corrugated material, its thickness (measured in ECT or Edge Crush Test), and the number of walls (single-wall, double-wall, or triple-wall).

For lightweight or non-fragile products, a single-wall corrugated box may be sufficient. However, for heavier or fragile items, consider using double-wall or triple-wall boxes for added strength and durability.

Selecting the Right Corrugated Material

Corrugated boxes are available in various grades of corrugated material, ranging from lightweight (e.g., 32 ECT) to heavy-duty (e.g., 71 ECT). The higher the ECT value, the stronger the box. Consider the weight of the product and the shipping distance when choosing the appropriate corrugated material grade.

Customizing the Box Design

If the standard box sizes and styles do not meet your specific packaging requirements, consider customizing the box design. Work with a packaging manufacturer or supplier who can create custom corrugated boxes based on your product’s dimensions and special needs.

Testing the Box

Before mass-producing the corrugated boxes, it is crucial to conduct testing to ensure that the packaging design can adequately protect the product during transit. Testing may include drop tests, vibration tests, compression tests, and other methods to assess the box’s structural integrity and performance.

Ordering the Corrugated Boxes

Once you have finalized the box dimensions, style, strength, and material, place an order with a reputable corrugated box manufacturer or packaging supplier. Provide them with the specifications and quantity required for your product.

Conclusion

Calculating the size of a corrugated box involves considering the dimensions of the product, selecting the appropriate box style, accounting for cushioning materials, and ensuring the box’s strength and structural integrity. Customizing the box design and conducting testing are essential steps to ensure the packaging can effectively protect the product during shipping. By following these steps, you can efficiently determine the ideal corrugated box size for your specific product and shipping needs.

Leave a Comment