Key Things to Consider When Opting for Packaging Tape

When it comes to packaging materials, packaging tape is an essential component that plays a crucial role in securing and sealing packages. Whether you are shipping products or simply organizing items for storage, choosing the right packaging tape is important to ensure the safety and integrity of your packages. There are several key factors to consider when opting for packaging tape, and in this guide, we will explore them in detail to help you make an informed decision.

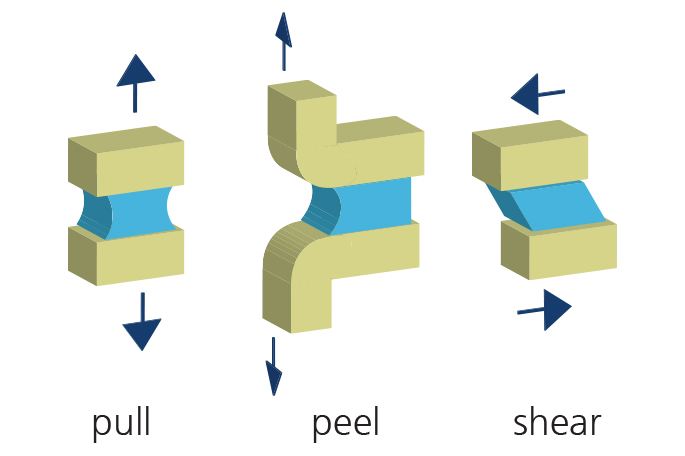

Adhesive Strength

One of the most important factors to consider when selecting packaging tape is its adhesive strength. The tape should have a strong adhesive that securely seals the package and prevents it from opening during transit or storage. Look for packaging tapes with high-tack adhesives that provide a strong bond to various surfaces, including cardboard, plastic, and other common packaging materials. Additionally, consider the application temperature range of the tape’s adhesive to ensure it performs well in different environmental conditions.

Durability

Packaging tapes should be durable enough to withstand the rigors of shipping and handling. Consider the thickness and tensile strength of the tape to determine its durability. Thicker tapes with higher tensile strength are generally more resistant to tearing and breaking. They provide better protection against package tampering and ensure that the tape remains intact throughout the transportation process. Opt for tapes that are specifically designed for heavy-duty applications if you are shipping or storing bulky and heavy items.

Compatibility

It’s essential to ensure that the packaging tape you choose is compatible with the materials you are sealing. Most packaging tapes work well with cardboard and corrugated boxes, but if you are using other types of packaging materials such as plastic bags or padded envelopes, make sure the tape adheres properly to them. Some tapes are specifically designed for use with certain materials, so check the product specifications to ensure compatibility.

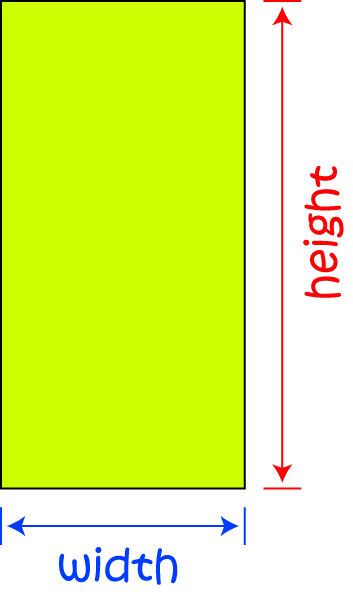

Width and Length

Consider the width and length of the packaging tape based on your specific needs. The width of the tape determines the coverage area and the amount of adhesive surface in contact with the package. Narrow tapes are suitable for sealing smaller packages or for applications where you need more precision. Wider tapes provide a larger adhesive surface and are better suited for sealing larger packages or reinforcing heavier loads. Additionally, consider the length of the tape roll to ensure it is sufficient for your packaging requirements. Longer rolls can be more cost-effective and minimize the need for frequent tape changes.

Ease of Use

The ease of use of packaging tape can significantly impact your packaging efficiency. Look for tapes that offer convenient features such as easy unwind, smooth application, and clean cutting. Tapes with smooth release coatings or technologies can help prevent sticking to the dispenser or tearing during application. Consider whether you need a manual dispenser or an automated packaging system for your tape application. Automated systems can improve productivity and ensure consistent tape application.

Tape Color and Transparency

Packaging tapes are available in various colors and transparency levels. While color may not directly affect the tape’s performance, it can be useful for organizing and identifying different packages or shipments. For example, using different colored tapes for different products or destinations can help streamline sorting and identification processes. Transparency, on the other hand, can be important when you want to maintain the aesthetics of your packaging or when you need to read or scan barcodes or other labels through the tape.

Environmental Considerations

In recent years, there has been an increasing focus on sustainable packaging solutions. If environmental considerations are important to you, look for packaging tapes that are made from recycled or biodegradable materials. Some tapes are manufactured using water-based adhesives, which can be more eco-friendly than solvent-based alternatives. Additionally, consider the tape’s recyclability and whether it is compatible with your existing recycling processes. Choosing environmentally friendly packaging tapes can contribute to your overall sustainability efforts.

Temperature Resistance

Temperature resistance is an important factor to consider, especially if you are shipping or storing packages in extreme temperature conditions. Different packaging tapes have varying temperature ranges at which they perform optimally. For example, if you are shipping packages to cold regions or using refrigerated storage, you may need tapes that can withstand low temperatures without losing their adhesive properties or becoming brittle. Similarly, if you are shipping packages to hot climates or using storage facilities without climate control, tapes that can withstand high temperatures without melting or losing their adhesive strength would be essential. Consider the temperature range requirements of your specific application and choose tapes that can withstand those conditions.

Tamper-Evident Features

In certain industries or for high-value shipments, tamper-evident packaging tapes can provide an added layer of security. These tapes are designed to leave visible evidence if someone attempts to tamper with the package. They often have specialized features such as perforations, security prints, or unique adhesives that make it apparent if the tape has been removed or tampered with. If security is a concern for your packages, consider using tamper-evident packaging tapes to deter unauthorized access and provide peace of mind.

Brand Reputation and Reliability

When choosing packaging tape, consider the reputation and reliability of the brand or manufacturer. Established brands often have a history of producing high-quality packaging materials and can provide consistent performance and customer support. Research customer reviews and ratings to gauge the experiences of other users with the tape you are considering. Additionally, consider factors such as the manufacturer’s commitment to quality control, certifications, and adherence to industry standards. Investing in trusted brands can help ensure that you are using reliable packaging tapes that meet your requirements.

Cost-Effectiveness

Packaging tape comes in a wide range of price points, and it’s important to consider the cost-effectiveness of the tape you choose. While it may be tempting to opt for the cheapest option, it’s crucial to balance cost with quality and performance. Cheaper tapes may have lower adhesive strength, durability, or temperature resistance, which can compromise the integrity of your packages. On the other hand, expensive tapes may have advanced features or specialized properties that you may not need for your specific application. Evaluate your packaging needs and budget to choose a tape that offers the right balance of performance and cost-effectiveness.

Industry-Specific Requirements

Different industries may have specific requirements when it comes to packaging tapes. For example, the medical and pharmaceutical industry may require tapes that are resistant to moisture or sterilization processes. The e-commerce industry may prioritize tapes that provide clear visibility of barcode labels for efficient scanning. If you belong to a particular industry, consider any specific regulations, standards, or unique requirements that may influence your choice of packaging tape. Consult industry guidelines or seek advice from experts to ensure compliance and optimal packaging performance.

Testing and Samples

Before committing to a particular packaging tape, consider requesting samples or performing testing to assess its suitability for your needs. Many manufacturers or distributors offer samples or small trial rolls that allow you to evaluate the tape’s adhesive strength, durability, and other performance factors. Testing the tape with your specific packaging materials, application methods, and environmental conditions can provide valuable insights into its performance. Take advantage of these opportunities to ensure that the chosen tape meets your expectations and requirements.

Storage Conditions

Lastly, consider the storage conditions of your packaging tape. To maintain the tape’s performance and integrity, it is important to store it properly. High temperatures, excessive humidity, or exposure to direct sunlight can degrade the adhesive properties of the tape over time. Make sure to store the tape in a cool, dry place, away from direct sunlight and extreme temperature fluctuations. Adhering to the recommended storage conditions can help prolong the shelf life and maintain the performance of the packaging tape.

In conclusion, choosing the right packaging tape requires careful consideration of various factors. Adhesive strength, durability, compatibility, width and length, ease of use, tape color and transparency, temperature resistance, tamper-evident features, brand reputation and reliability, cost-effectiveness, industry-specific requirements, testing and samples, and storage conditions are all important aspects to take into account. By evaluating these factors and selecting a tape that aligns with your specific needs, you can ensure the safety and integrity of your packages during shipping, handling, and storage.

Leave a Comment