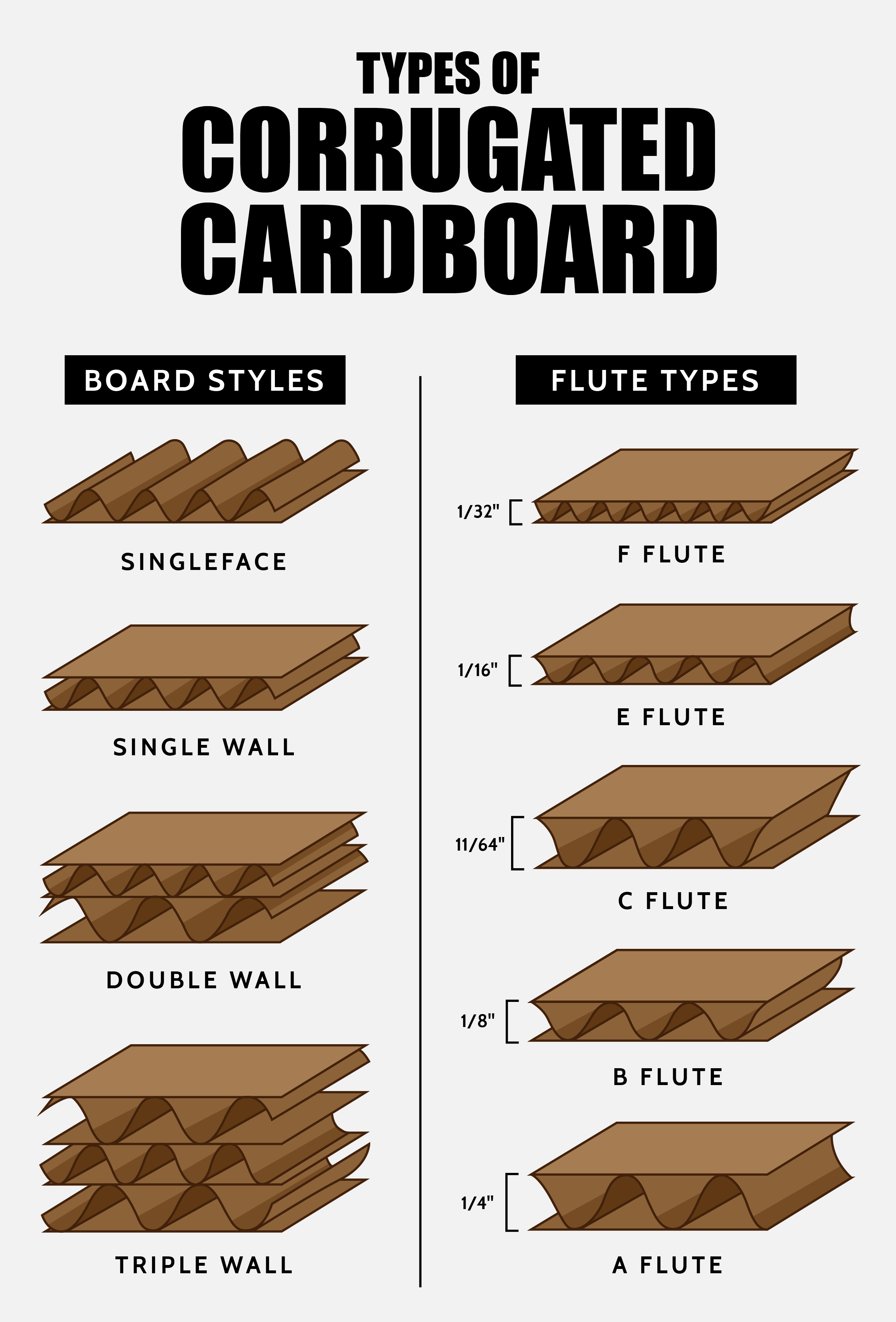

What Are The Major Types Of Flutes Used For Corrugated Boxes

Corrugated boxes are widely used for packaging and shipping various products due to their durability and strength. Flutes, also known as corrugations, are a crucial component of corrugated boxes that provide rigidity and structural integrity. There are several major types of flutes used in the manufacturing of corrugated boxes, each offering specific advantages depending on the intended use of the box. In this response, we will explore these major types of flutes used for corrugated boxes and discuss their characteristics.

A-Flute:

The A-flute is the largest and thickest flute profile, providing excellent cushioning and compression resistance. It has a height of approximately 4.7 mm (3/16 inches) and offers superior stacking strength, making it suitable for heavy-duty applications. A-flute corrugated boxes are commonly used for shipping fragile and delicate items like glassware, ceramics, and electronics. The larger flute size of A-flute boxes also provides good insulation properties, protecting the contents from temperature changes.

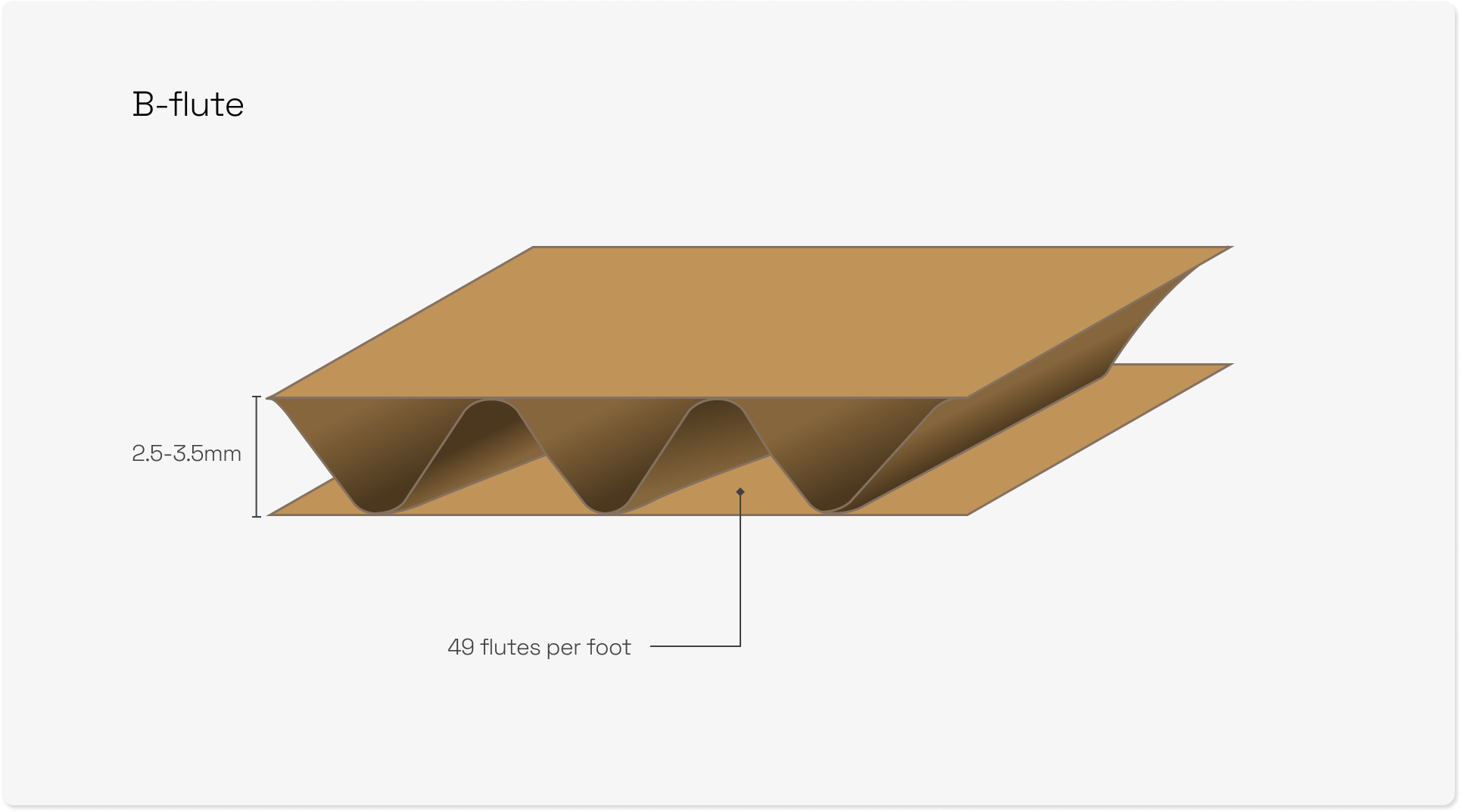

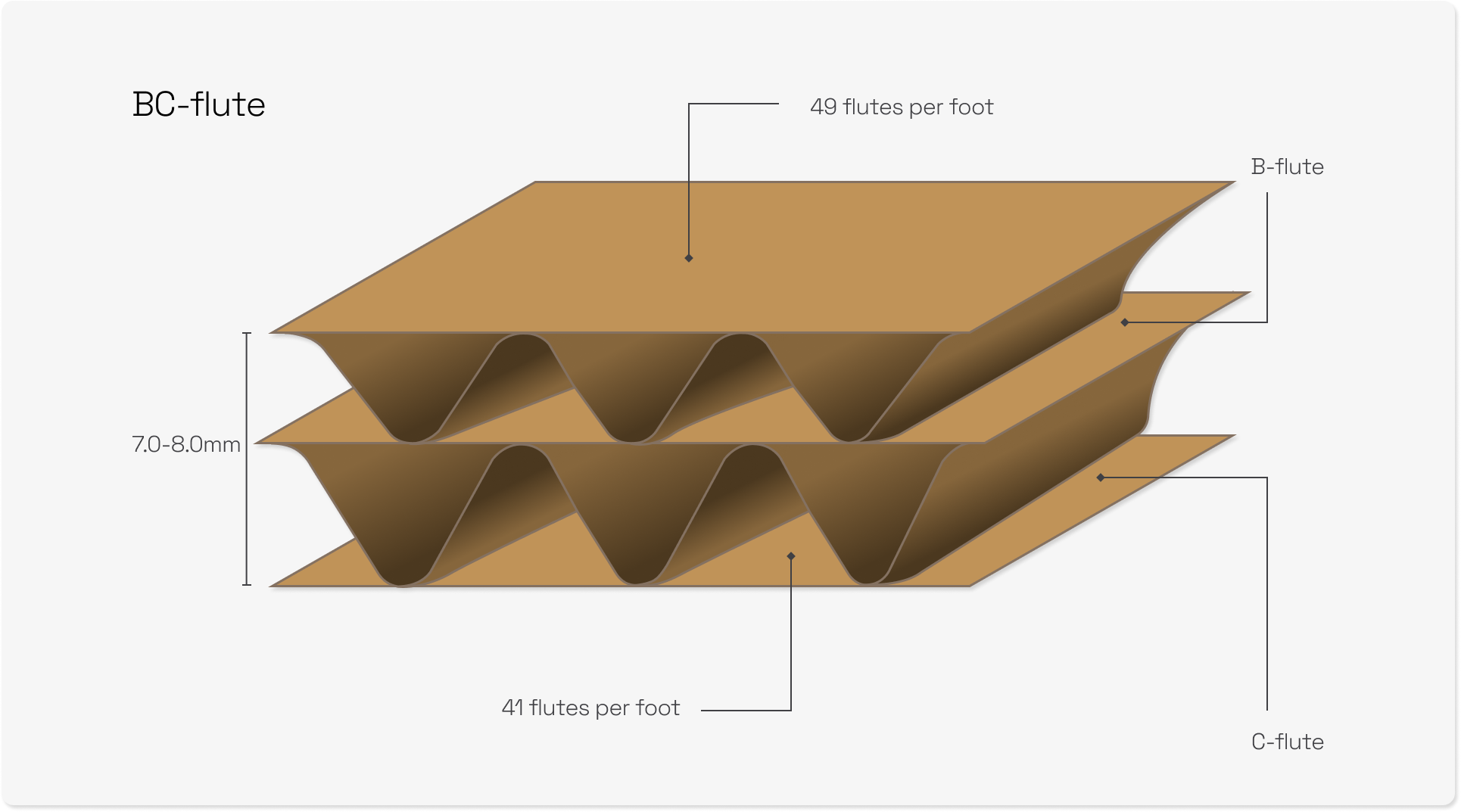

B-Flute:

B-flute is the second most common flute type and is characterized by its moderate thickness and high stacking strength. It has a height of around 2.6 mm (1/8 inches), making it suitable for applications where space is a constraint. B-flute boxes are often used for retail packaging, point-of-sale displays, and inner packaging for various products. The smaller flute size of B-flute boxes provides a smoother printing surface, allowing for high-quality graphics and text.

C-Flute:

C-flute is the most widely used flute profile globally, offering a balance between stacking strength and printing capabilities. It has a height of approximately 3.6 mm (9/64 inches) and provides good crush resistance and cushioning properties. C-flute corrugated boxes are versatile and find applications in various industries, including food, e-commerce, consumer goods, and industrial packaging. They are suitable for packaging products of medium weight and are often used for shipping items like books, toys, and household goods.

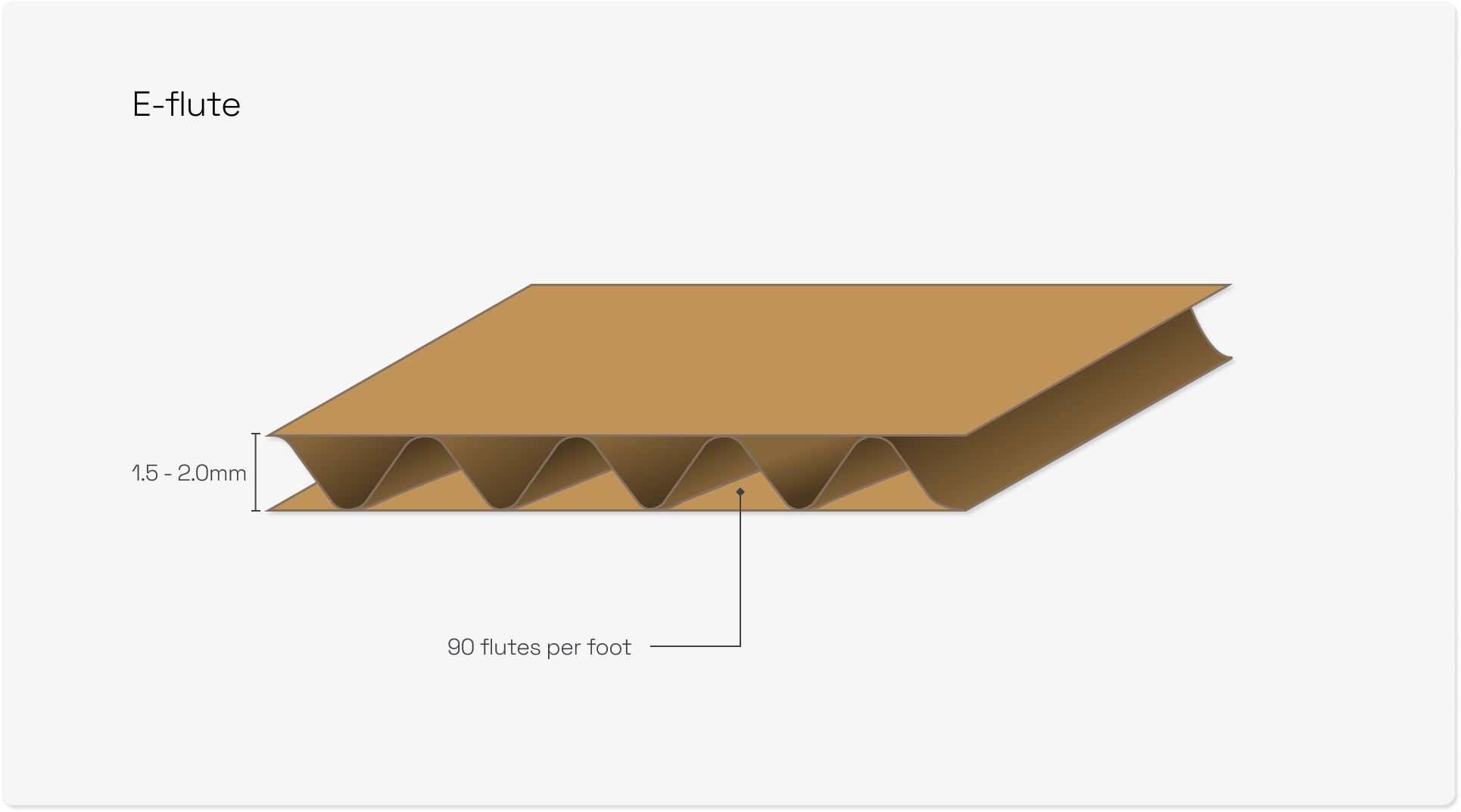

E-Flute:

E-flute is a thinner and denser flute profile compared to A, B, and C flutes, with a height of approximately 1.6 mm (1/16 inches). It offers excellent printability, structural strength, and is ideal for packaging applications that require a compact and lightweight design. E-flute boxes have a smooth surface, making them suitable for retail packaging, point-of-purchase displays, and premium packaging for products like cosmetics, electronics, and small appliances. They provide a high level of detail in printing and enhance the visual appeal of the packaged goods.

F-Flute:

F-flute is the newest addition to the flute profiles and is known for its exceptionally fine fluting, with a height of approximately 0.8 mm (1/32 inches). It offers a high level of crush resistance and is ideal for applications that require enhanced protection and a sleek appearance. F-flute corrugated boxes are commonly used for luxury packaging, high-end consumer goods, and delicate items like glass bottles and jewelry. The fine fluting also allows for precise die-cutting and intricate box designs.

It’s worth noting that there are other less commonly used flute profiles as well, such as D-flute, N-flute, and micro-flute. D-flute is thicker than E-flute but thinner than C-flute, offering a balance between cushioning and stacking strength. N-flute is a narrow flute profile primarily used for applications requiring high-quality printability and dimensional stability. Micro-flute refers to flute sizes smaller than E-flute and is often used for compact packaging of small items or promotional materials.

In summary, the major types of flutes used for corrugated boxes include A-flute, B-flute, C-flute, E-flute, and F-flute. Each flute profile offers specific advantages in terms of stacking strength, cushioning, printability, and appearance. The selection of the flute type depends on the weight and fragility of the packaged product, the desired level of protection, and the visual presentation requirements. By understanding the characteristics of different flute profiles, manufacturers can choose the most appropriate flute type to meet the specific packaging needs of their products.

Leave a Comment