How does the packaging help to preserve the flavor and aroma of the tobacco?

Packaging plays a crucial role in preserving the flavor and aroma of tobacco products. The quality of the tobacco, its processing, and the packaging all contribute to the overall experience of smoking or using tobacco in various forms. In this response, we will explore the significance of packaging in preserving the flavor and aroma of tobacco in detail, covering different types of tobacco products and their packaging considerations.

Introduction to Tobacco Packaging:

Tobacco packaging serves multiple purposes, including protecting the product from external factors, maintaining its freshness, and enhancing the consumer experience. It acts as a barrier against moisture, light, air, and other potential contaminants that can adversely affect the quality of tobacco. Packaging also serves as a means of branding and marketing, providing essential information to consumers while complying with relevant regulations.

Protection against Moisture:

Moisture is one of the primary factors that can impact the flavor and aroma of tobacco. Excessive moisture can lead to mold growth, degradation of tobacco leaves, and the development of off-flavors. Proper packaging materials with moisture barrier properties, such as aluminum foil or high-quality laminates, are used to create a protective shield around the tobacco, preventing moisture absorption and maintaining its optimal moisture content.

Prevention of Flavor Loss due to Oxidation:

Oxygen is another significant factor that can cause the deterioration of tobacco flavor and aroma. Exposure to air can lead to oxidation, resulting in the breakdown of organic compounds and the loss of volatile flavor constituents. Packaging materials with oxygen barrier properties, such as metalized films or multi-layer laminates, are employed to restrict the entry of oxygen into the tobacco product, thus minimizing flavor loss.

Light Protection:

Light, particularly ultraviolet (UV) light, can cause significant flavor and aroma degradation in tobacco. UV radiation can break down organic molecules and alter their chemical composition, leading to undesirable changes in flavor profiles. Packaging designs often incorporate light-blocking materials or opaque layers to shield the tobacco from direct light exposure and preserve its flavor and aroma integrity.

Aroma Preservation:

Tobacco products often possess unique and desirable aromatic characteristics. Proper packaging helps retain these aromas, preventing their loss or contamination. By using materials with low aroma permeability, such as specialized films or laminates, the packaging can act as a barrier against external odors or flavors that could potentially affect the tobacco’s aroma.

Sealing and Closure Mechanisms:

Effective sealing and closure mechanisms are crucial in preventing the entry of external contaminants and preserving the freshness of tobacco. Packaging is designed to create an airtight seal, minimizing airflow into and out of the package. Common sealing methods include heat-sealing, zip-lock closures, or resealable adhesive strips, which help maintain the tobacco’s flavor and aroma by preventing the exchange of air and moisture.

Packaging Formats for Different Tobacco Products:

Various tobacco products, such as cigarettes, cigars, pipe tobacco, chewing tobacco, and snuff, have different packaging requirements to preserve their unique characteristics.

Cigarettes:

Cigarettes are typically packaged in cartons or soft packs. Cartons provide additional protection against physical damage and often incorporate foil lining or cellophane wrapping to maintain freshness. Soft packs usually have an inner foil or paper liner that serves as a moisture barrier, protecting the cigarettes from moisture loss or gain.

Cigars:

Cigars are typically stored in individual tubes or boxes, which offer protection against physical damage and environmental factors. Cedar wood boxes are commonly used as they help regulate humidity and contribute to the flavor development of the cigars over time. Tubes are often made from aluminum or other materials with excellent moisture and light barrier properties.

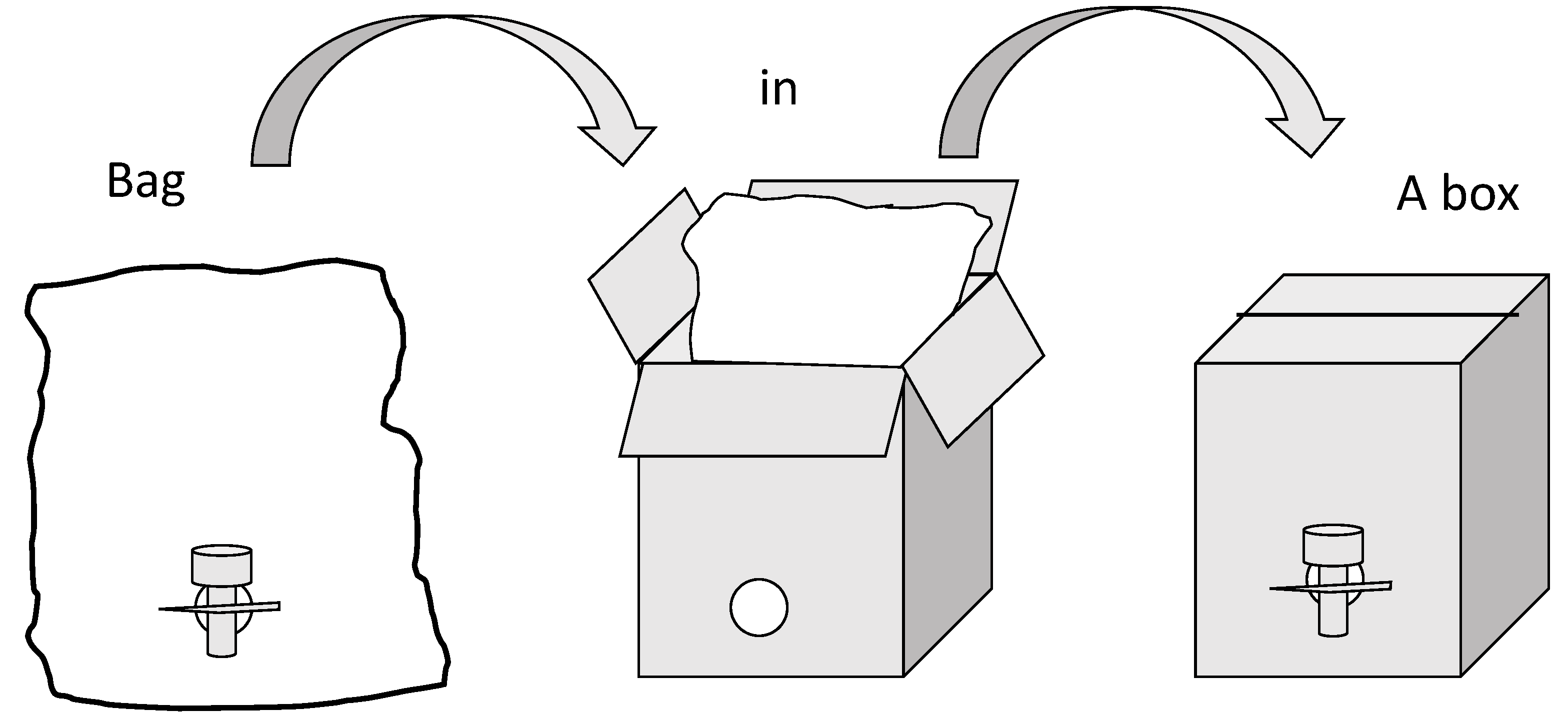

Pipe Tobacco:

Pipe tobacco is often packaged in tins or pouches. Tins provide excellent protection against moisture, light, and air due to their airtight construction. Some tins also include a vacuum-sealed inner lining, ensuring optimal freshness. Pouches, typically made from multilayer laminates, offer convenience and resealable features to preserve the tobacco’s moisture and flavor.

Chewing Tobacco and Snuff:

Chewing tobacco and snuff products are commonly packaged in plastic cans or tins with moisture-sealing lids. The containers are designed to prevent moisture absorption or loss, maintaining the tobacco’s moisture content and flavor. Some cans also incorporate a moisture-regulating inner liner, such as foils or moisture-resistant papers, to provide additional protection.

Regulatory Compliance:

Packaging for tobacco products must comply with various regulations, including health warnings, ingredient labeling, and other legal requirements imposed by different jurisdictions. These regulations aim to ensure consumer safety, provide relevant information, and discourage tobacco use. Packaging designs must balance the need for regulatory compliance with preserving the flavor and aroma of the tobacco product.

Consumer Experience and Branding:

Packaging also plays a vital role in shaping the consumer experience and conveying the brand image. Visual elements, such as color schemes, graphics, and logos, are used to establish brand identity and attract consumers. Additionally, packaging may include features such as easy-open mechanisms, tactile textures, or embossing, enhancing the overall experience and reinforcing brand loyalty.

Conclusion:

Packaging is an essential component in preserving the flavor and aroma of tobacco products. Through effective moisture barrier properties, oxygen and light protection, proper sealing mechanisms, and aroma preservation, packaging helps maintain the quality and freshness of tobacco. Additionally, packaging formats for different tobacco products address specific needs while complying with relevant regulations. By carefully considering packaging design and materials, tobacco manufacturers can ensure that consumers enjoy the intended flavor and aroma profiles of their products.

Leave a Comment