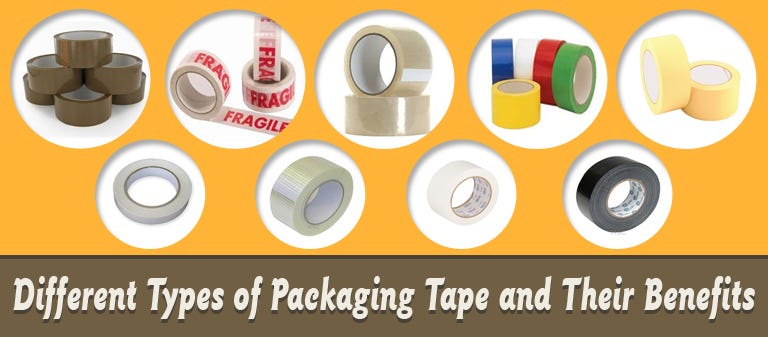

Types of Packaging Tapes and its Benefits

Packaging tapes play a crucial role in securing and sealing packages for shipping, storage, and various other purposes. They come in a wide range of types, each designed to meet specific packaging requirements. In this article, we will explore some of the most common types of packaging tapes and the benefits they offer.

Acrylic Tape:

Acrylic tape is one of the most widely used packaging tapes. It is made from a water-based acrylic adhesive, which provides excellent adhesion to a variety of surfaces, including cardboard, plastic, and metal. The benefits of acrylic tape include good clarity, moisture resistance, and high UV resistance. It is an ideal choice for general-purpose packaging and carton sealing applications.

Hot Melt Tape:

Hot melt tape, also known as synthetic rubber tape, is made from a synthetic rubber adhesive. It offers superior holding power and is highly resistant to temperature changes, making it suitable for use in cold or hot environments. Hot melt tape provides instant adhesion, ensuring quick and secure sealing of packages. It is commonly used for heavy-duty applications, such as sealing bulky or heavy boxes.

Filament Tape:

Filament tape is a reinforced packaging tape that consists of a strong polypropylene backing and fiberglass filaments embedded within the adhesive. It offers exceptional tensile strength and is resistant to tearing, making it ideal for bundling and reinforcing heavy items. Filament tape is commonly used in industries such as manufacturing, construction, and logistics.

Paper Tape:

Paper tape, as the name suggests, is made from kraft paper and a water-based adhesive. It is an eco-friendly packaging tape option, as it is biodegradable and recyclable. Paper tape provides good adhesion to various surfaces and is often used for sealing lightweight packages, as well as for arts and crafts projects. It can be easily torn by hand, eliminating the need for scissors or cutters.

PVC Tape:

PVC tape, also known as vinyl tape, is made from polyvinyl chloride and a rubber-based adhesive. It offers excellent flexibility and conformability, allowing it to adhere to irregular surfaces with ease. PVC tape provides good resistance to moisture, chemicals, and abrasion, making it suitable for both indoor and outdoor applications. It is commonly used in the electrical and construction industries.

Double-Sided Tape:

Double-sided tape is coated with adhesive on both sides and is often used for bonding two surfaces together. It is available in various forms, including foam tape, tissue tape, and film tape. Double-sided tape offers a strong bond and can be used for mounting, splicing, and laminating applications. It is commonly used in the signage, printing, and automotive industries.

Masking Tape:

Masking tape is a versatile adhesive tape that is easy to tear and remove without leaving residue behind. It is made from a thin and easy-to-conform paper backing and a pressure-sensitive adhesive. Masking tape is commonly used for painting and general-purpose applications, such as holding, bundling, and labeling. It provides good adhesion to a variety of surfaces and can be written on with markers.

Security Tape:

Security tape is specifically designed to provide tamper-evident sealing for packages. It contains a pattern or message that becomes distorted or reveals a hidden message when the tape is tampered with. Security tape helps prevent unauthorized access to packages and provides a visual indication of tampering. It is commonly used in industries where the integrity of the contents is crucial, such as pharmaceuticals, electronics, and banking.

Gummed Paper Tape:

Gummed paper tape, also known as water-activated tape, is made from kraft paper and a water-based adhesive. It requires water for activation, which forms a strong bond with the carton surface upon drying. Gummed paper tape offers excellent adhesion, tamper resistance, and high holding power. It is commonly used for sealing heavy or valuable packages, as well as for branding purposes.

Specialty Tapes:

In addition to the types mentioned above, there are various specialty tapes available for specific packaging needs. These include freezer tape for sealing packages in cold storage, foam tape for cushioning and insulation, electrical tape for insulating and protecting electrical wires, and label protection tape for securing and protecting shipping labels. Specialty tapes cater to unique packaging requirements and provide specialized benefits.

In conclusion, packaging tapes are essential for securing and sealing packages effectively. Choosing the right type of tape based on the specific application can enhance packaging efficiency, ensure product protection, and improve customer satisfaction. Whether it’s acrylic tape for general sealing, filament tape for heavy-duty bundling, or specialty tape for specific needs, the diverse range of packaging tapes available in the market caters to a wide range of packaging requirements.

Leave a Comment